Engineering Excellence in Action

Precision manufacturing solutions trusted by industry leaders for over 70 years

Delivering Solutions That Matter

At Fortis Mechanical, we don't just manufacture parts—we engineer solutions that become integral to world-class products.

Our approach combines decades of manufacturing expertise with continuous innovation, resulting in long-term partnerships with leading brands across the power tool, automotive, medical, and industrial sectors. From initial concept through high-volume production, we work alongside our customers to develop precision components and assemblies that meet the most demanding performance requirements.

Our global footprint and advanced manufacturing capabilities enable us to deliver cost-effective solutions without compromising quality.

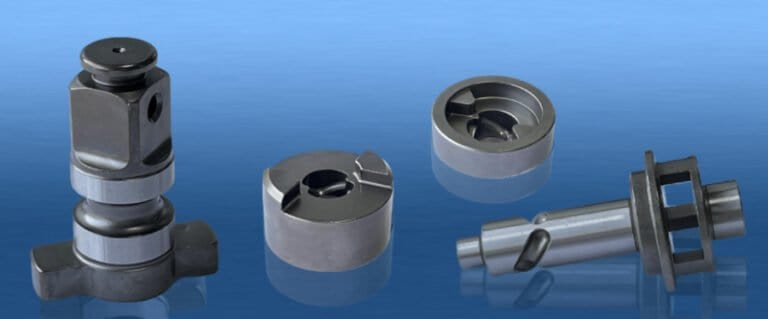

High-Performance Impactor Systems

Two Decades of Continuous Innovation in Power Tool Technology

Since 2000, Fortis has been a trusted partner in developing mission-critical impactor components for the professional power tool industry. Our journey began with basic impactor, cam carrier, and anvil manufacturing and has evolved into a comprehensive solution encompassing advanced materials, multiple forging processes, and torque ratings from 800Nm to 3000Nm.

Development Timeline

2000-2010

Established impactor manufacturing capabilities in USA and China, partnering with leading power tool brands to develop cam carrier and anvil processes.

2012

Developed cold forging process for impactor components, improving material utilization and part consistency while reducing costs.

2013-2015

Expanded torque range to 800-1200Nm, supplying hammer, cam shaft, and anvil components to Milwaukee Tools and other major OEMs.

2018-2019

Introduced hot forging process and developed special materials for impactor, cam carrier, and anvil applications. Achieved 1500Nm torque rating.

2021-2022

Reached new milestone with 3000Nm impact capability, establishing additional manufacturing capacity in Mexico and Ningbo to support growing demand.

Key Technologies

- Cold forging for precision and material efficiency

- Hot forging for complex geometries

- Special material development for extreme durability

- Multi-axis CNC machining for tight tolerances

- Advanced heat treatment processes

Customer Benefits

- Continuous performance improvements over 22-year partnership

- Cost reduction through process innovation

- Reliable supply chain with global manufacturing footprint

- Engineering support from prototype through high-volume production

Complete Gearbox Design & Assembly

Full-Service Engineering from Concept to Production

Fortis Mechanical provides end-to-end gearbox solutions, from initial design and feasibility studies through precision assembly and testing. Our work with DEWALT demonstrates our capability to serve as a complete manufacturing partner, handling both component production and final assembly under one roof.

Our Approach

Design & Engineering

Our engineering team worked closely with our customer to develop gearbox designs that balance performance, manufacturability, and cost. We provide feasibility analysis, prototype development, and proof-of-concept testing to validate designs before committing to production tooling.

Precision Manufacturing

All gearbox components are manufactured in-house using advanced CNC machining centers, multi-axis lathes, and precision grinding equipment. This vertical integration ensures consistent quality and tight tolerances across all components.

Assembly & Testing

We design and build custom assembly cells with mistake-proofing features and automated testing. Each gearbox undergoes rigorous quality checks including dimensional verification, leak testing, and durability testing to ensure it meets specifications.

Key Capabilities

- New product design and feasibility analysis

- Prototype and proof-of-concept development

- Precision machining of all gearbox components

- Computerized assembly cell design and build

- Leak test and durability test design

- Full automation or pockets of automation based on volume

- Advance Product Quality Planning (APQP)

Customer Benefits

- Single-source responsibility for complete gearbox solution

- Reduced development time through integrated engineering and manufacturing

- Superior quality through vertical integration

- Flexible assembly solutions from low to high volume

- Global supply chain management

Industries Served

- Professional power tools

- Industrial equipment

- Automotive

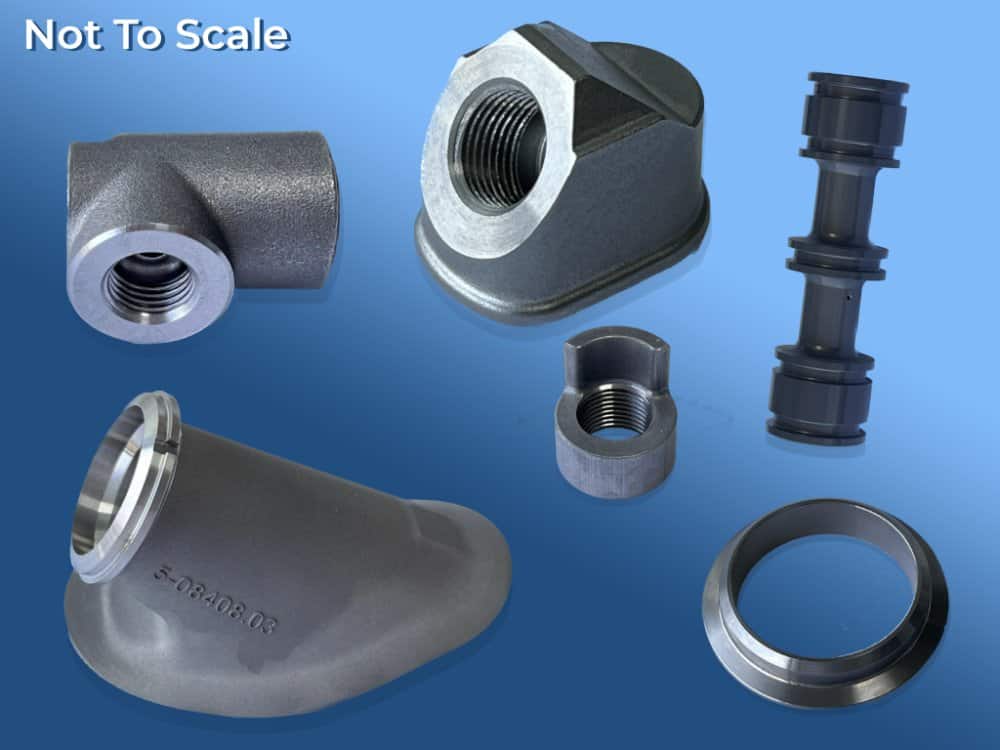

Automotive-Grade Precision Components

Meeting the Demanding Standards of the Automotive Industry

Fortis Mechanical brings decades of precision manufacturing experience to the automotive sector, supplying critical components to tier-one suppliers including Sango and BorgWarner. Our automotive work demonstrates our ability to meet the rigorous quality standards, high-volume requirements, and cost targets demanded by this industry.

Our Automotive Capabilities

Fortis is IATF 16949:2016 certified, demonstrating our commitment to automotive quality management systems. We employ Six Sigma methodologies and statistical process control to ensure repeatability and reproducibility across millions of parts.

Our automotive manufacturing combines precision machining, cold forging, and assembly capabilities to deliver complete solutions. We support just-in-time delivery through Kan-ban systems and maintain 24/7 operations to meet the demanding production schedules of automotive manufacturers.

Key Technologies

- IATF 16949:2016 certified quality systems

- Six Sigma process control

- High-speed CNC machining centers

- Cold forging for high-volume production

- Automated inspection and testing

- Global logistics and supply chain management

Customer Benefits

- Automotive-grade quality systems and certifications

- High-volume production capacity with consistent quality

- Cost-competitive manufacturing through global footprint

- Just-in-time delivery and supply chain management

- Value engineering support for cost reduction

- Optimized North American Supply Chain compliant with USMCA

Industries Served

- Automotive OEMs

- Tier-one suppliers

Why Leading Brands Choose Fortis

Engineering Excellence

Over 70 years of precision manufacturing expertise with continuous investment in advanced technologies and processes.

Global Footprint

Manufacturing facilities in USA, Mexico, and China provide flexible capacity and reliable supply chain management.

Long-Term Partnerships

We build lasting relationships with customers through continuous innovation, quality, and responsive service.

Ready to Develop Your Next Solution?

Let our team of engineers review your project and provide a comprehensive quote.

If you need more information, contact us with the additional details you need.