Global Manufacturing Excellence

Strategic operations across three countries, delivering precision manufacturing solutions worldwide

Our Global Operations Network

Fortis Mechanical operates an integrated network of advanced manufacturing facilities strategically positioned across North America and Asia. This footprint is a strategic tool for our partners, allowing them to build resilient supply chains that balance regional production for local markets with global cost efficiencies. With over 50,000 square meters of manufacturing space and 500+ skilled associates, we deliver precision-engineered components and assemblies to customers worldwide.

Our facilities combine cutting-edge technology with decades of manufacturing expertise, featuring over 1,000 CNC machines and robots working in concert to produce mission-critical components for the industrial, automotive, medical, and power tool industries.

Each location is strategically selected to serve regional markets while maintaining our commitment to quality, innovation, and customer partnership.

Our Global Footprint

Integrated Global Manufacturing

Our strategically positioned facilities work as an integrated network, each contributing specialized capabilities while maintaining consistent quality standards across all operations. This global footprint enables us to serve customers efficiently regardless of their location, while providing flexibility in capacity, technology, and logistics.

Combined Capabilities

- Precision CNC Machining: Multi-axis machining, Swiss machining, turning, milling, grinding

- Cold Forging: Proprietary processes for high-strength components

- Assembly: Manual and automated assembly with mistake-proofing

- Quality Control: CMM inspection, automated testing, 100% verification

- Automation: Lights-out machining, robot-operated systems, automated material handling

- Engineering Support: Design collaboration, prototyping, process optimization

Technology Infrastructure

- Over 1,000 CNC machines and robots

- Automated inspection systems

- Digital monitoring and control

- Coordinate measuring machines

- Ultrasonic cleaning systems

Quality Standards

- ISO 9001:2015 Certified (company-wide)

- IATF 16949:2016 Certified (Suzhou)

- PFMEA-driven quality processes

- LEAN manufacturing principles

- 6-Sigma quality execution

Monterrey, Mexico

North American Manufacturing Hub

In the heart of Monterrey’s industrial district stands our North American manufacturing base, the successor facility to our original Philadelphia operations. This newest location represents the culmination of our decades of manufacturing advancements and is furnished with the latest machining, assembly, and cold forging capabilities.

As a fully-owned subsidiary, our Monterrey facility combines advanced automation with skilled craftsmanship to deliver precision components for customers seeking to optimize their North American supply chains. The facility features state-of-the-art CNC machining centers, automated lathes, precision grinders, and our proprietary cold forging technology.

Managed by experienced manufacturing professionals, the Monterrey operation exemplifies our commitment to quality and innovation. The facility includes dedicated quality control areas with coordinate measuring machines, ultrasonic cleaning systems, and comprehensive packaging capabilities to ensure products meet exacting specifications.

Key Capabilities

- Precision CNC Machining

- Automated Assembly

- Cold Forging

- Coordinate Measuring Machine (CMM) Quality Control

- Ultrasonic Cleaning

- Complete Packaging Services

Certifications

- IMMEX Certified

- PROSEC Certified

Strategic Advantage

Optimally positioned for customers seeking nearshoring opportunities, this USMCA-compliant operation provides seamless access to both United States and Mexican markets with reduced lead times and logistics costs.

Suzhou, China

High-Mix Production Specialist

Our Suzhou facility represents world-class manufacturing excellence, supplying precision machined components and assemblies to leading industrial tool manufacturers and automotive OEMs. This operation specializes in high-mix, low-to-medium volume production, making it ideal for customers requiring flexibility and responsiveness.

The facility features advanced automated inspection systems and lights-out machining capabilities, enabling continuous production with minimal human intervention. This combination of automation and skilled oversight ensures consistent quality while maximizing efficiency.

Operating under rigorous quality standards and utilizing LEAN manufacturing principles, Suzhou delivers components that meet the most demanding specifications for performance-critical applications.

Key Capabilities

- Precision CNC Machining

- Complex Assemblies

- Automated Inspection Systems

- Lights-Out Machining

- High-Mix Production

Certifications

- IATF 16949:2016 Certified

- ISO 9001:2015 Certified

Manufacturing Philosophy

LEAN tools and processes drive continuous improvement, ensuring optimal efficiency and quality in every component produced.

Ningbo, China

Cold Forging & Precision Machining Center

Ningbo serves as our largest precision machining and cold forging facility, producing high volumes of mission-critical components for cordless impact wrenches used by construction professionals worldwide. This vertically integrated operation showcases our manufacturing depth and technical expertise.

The facility’s proprietary cold-forging process transforms steel bars into near-net-shape forms ready for precision machining, significantly reducing material waste while ensuring superior mechanical properties. This vertical integration provides complete control over the manufacturing process, from raw material to finished component.

Ningbo’s scale and specialization enable us to deliver the consistent quality and reliability demanded by leading power tool manufacturers, supporting their reputation for professional-grade performance.

Key Capabilities

- Large-Scale Precision Machining

- Proprietary Cold Forging Process

- Vertically Integrated Operations

- High-Volume Production

- Steel Bar to Finished Component

Specialization

Mission-critical components for cordless impact wrenches and construction industry power tools.

Strategic Advantage

Vertical integration from raw material to finished component ensures quality control, reduces lead times, and optimizes costs for high-volume production.

Nantong, China

Digital Factory for Automotive Excellence

Nantong represents the future of manufacturing—a true “Digital Factory” specialized in producing precision machined components for automotive OEMs. This facility showcases our commitment to Industry 4.0 principles and advanced manufacturing technology.

The operation features multiple advanced robot-operated machining centers working in coordination with automated material handling equipment, enabling efficient lights-out production. Digital monitoring and control systems provide real-time visibility into every aspect of the manufacturing process, ensuring quality and enabling rapid response to any variations.

This integration of robotics, automation, and digital systems positions Nantong at the forefront of modern manufacturing, delivering the precision and consistency required by the automotive industry’s most demanding applications.

Key Capabilities

- Robot-Operated Machining Centers

- Automated Material Handling

- Lights-Out Operation

- Digital Process Monitoring

- Real-Time Quality Control

Specialization

- Precision machined components for automotive OEM applications.

Technology Leadership

Advanced digital systems and robotics enable unprecedented levels of automation, quality, and efficiency.

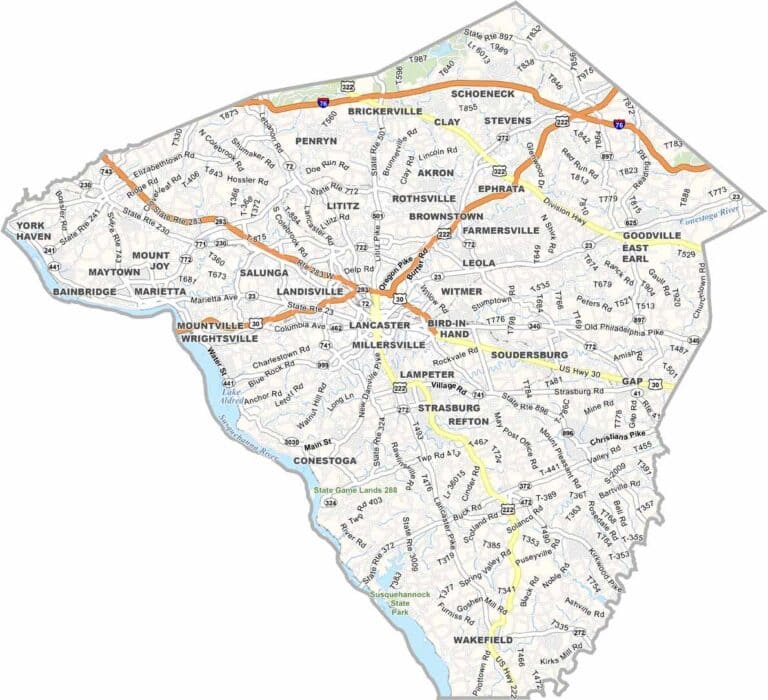

Lancaster, Pennsylvania, USA

North American Headquarters

Our Lancaster, Pennsylvania location serves as Fortis Mechanical’s North American headquarters, housing our sales, engineering, and prototyping operations. This facility provides critical support to our global manufacturing network, bridging customer needs with our production capabilities.

The engineering team collaborates closely with customers to develop innovative solutions, while our prototyping capabilities enable rapid iteration and validation before full-scale production. This customer-facing operation ensures responsive communication and technical support for North American clients.

Key Functions

- Sales and Customer Service

- Engineering and Design Support

- Prototyping Services

- Technical Collaboration

Strategic Role

Provides direct access to Fortis expertise for North American customers, facilitating seamless communication and rapid response to technical requirements.

Partner with Our Global Operations

Let our team of engineers review your project and provide a comprehensive quote.

If you need more information, contact us with the additional details you need.