About Us

FORTIS GROUP

We are a global supplier of precision machined components and assemblies with a manufacturing operation supported by proprietary cold forging technology. We are a US company with manufacturing facilities in North America & Asia spanning over 50,000 square meters.

Industries served comprise that of power tools, transportation, lawn & garden, outdoor equipment, and industrial OEMs. Other industries within the scope of the company include medical and off-road vehicle & equipment.

FORTIS’ extensive experience in supplying medium to high production volumes makes us an ideal partner for on-shoring and contract manufacturing projects. Our global staff of technical and program managers are experienced in planning and implementing new business awards utilizing LEAN tools and APQP processes. The Fortis Group holds the financial and implementation resources necessary to successfully handle multiple new production projects, and a leadership team with extensive experience in managing successful manufacturing operations in Europe, Asia, and North America.

With over 1000 CNC machines and robots, Fortis’ world-class factories utilize pockets of automation (POA) for optimum flexibility in adapting to today’s ever-changing market demands and product trends. This operating philosophy is complemented by Fortis’ in-house capability to develop, design, and build production fixtures, test machines, and mistake-proofed assembly cells. We provide customers with manufacturing engineering support during new product development and production stages including rapid prototyping activities.

FORTIS traces its history to building machine tools of the 1950s. The company moved through several product line transformations in the following decades. In the year 2000, these changes evolved into our current business model. Fortis has since experienced phenomenal growth from its Philadelphia operation to now becoming an advancing global force in precision machining and assembly. We are capable and committed to continuing this trajectory of growth today.

Oddie Leopando

CEO

Quality Assistance

Global Leadership

Employees

Proven Record...Forward Looking

Company Mission

To produce precision machined component and assemblies requiring custom engineered solutions, providing our customers with high value from our supply chain expertise.

The Fortis Vision

Fortis is a trusted producer of mission-critical components and sub-assemblies for integration into the world-class products that better our lives and move our world forward. We focus on growth of precision machining, cold forging, and assembly of products for OEMs in North America, Asia, and Europe.

We serve superior value to our customers by providing globally competitive raw material sources, 6-Sigma quality execution, and deployment of LEAN manufacturing principles.

Our unique value proposition empowers our business to continue growing globally as we leverage synergies between traditional CNC machining and automation.

Our Quality Commitment

Fortis and its subsidiaries are committed to achieving customer satisfaction by consistent and continual improvement of its manufacturing products and services while upholding the standards set by its Quality Management System and applicable standards and regulations.

Our Values

Long-term customer satisfaction and retention is our highest, most valued priority

We strive to foster a culture of learning and improvement as each company associate is encouraged to achieve maximum individual potential as an empowered team member

We strengthen our competitive advantage by streamlining processes & compressing cycle times to maximize efficiency

Accountability and transparency at all levels are integral and indispensable to our company’s operation

We hold every associate to high standards of achievement and output

We always share technologies and best practices in cooperation with our supplier partners

Our diverse engineering talent excel at creating innovative designs, inventing new manufacturing techniques, and reducing costs

Follow our development history

2000

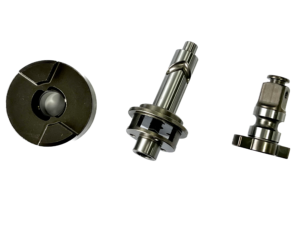

Development and production of Hammer, Cam Shaft, and Anvil processes in Philadelphia, PA

2010

Established location in Suzhou, China

2012

Developed proprietary cold-forging process

2013

Developed 800-1200nm Impactor parts

2014

Established Wujiang factory location

2015

Begin supplying parts to Milwaulkee Tools and BorgWarner

2016

Begin supplying automobile parts to Sango

2018

Developed hot forging process and 1500 nm Impactor

2019

Developed special material for Hammer, Cam Shaft, and Anvil

2021

Established factory location in Monterrey, Mexico

2022

Established new factory in Ningbo

2022

Developed 3000nm Impactor

2022

Established new factory in Nantong