Why Us

Global Footprint

Headquartered in USA with operations in Mexico & China. Adaptable to changing markets, logistical demands, and customer needs.

Full Service Supplier

Custom engineered solutions with support and expertise every step along the way, from early product conception to prototyping, testing, delivery, and maintenance.

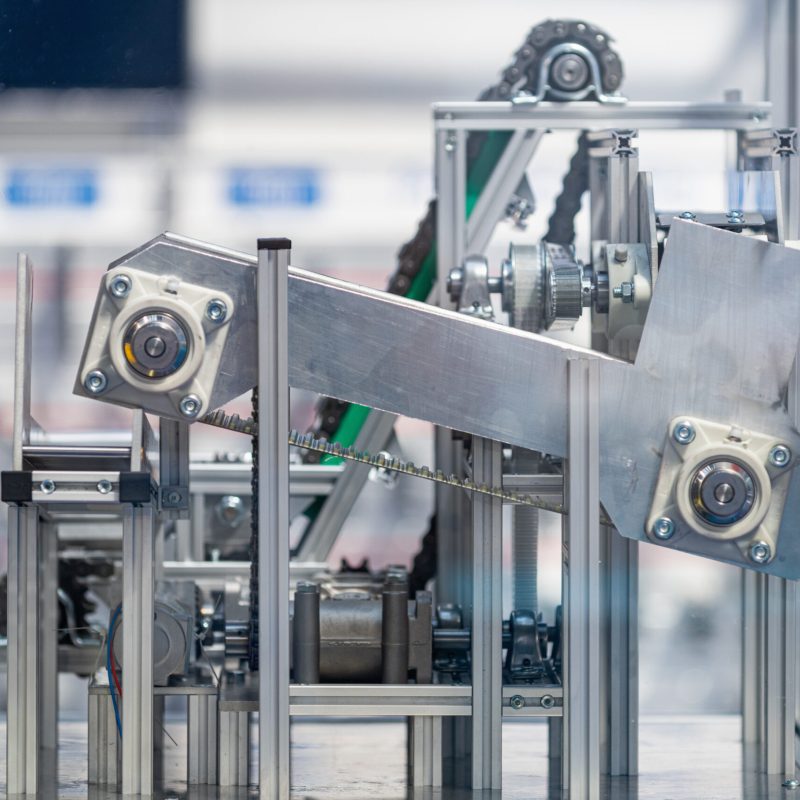

Cutting Edge Technology

Advanced manufacturing methods include proprietary cold-forging process and precision CNC assembly in state-of-the-art production facilities. Pockets of automation and full automation.

Mistake-Proof Processes

Focused and engineered quality assurance with automated mistake-proofing and real-time metrics driven by PFMEA. Emphasis on repeatability & reproducibility.

Supply Chain Management

Over 13 years of continuous experience in Supply Chain Management and global logistics management with supply bases in Asia and beyond. Knowledgable and adaptable to current changes and challenges.

Competitive Global Pricing

Delivering competitive cost-effective solutions for global customers and North American on-shoring projects with a reliable low-cost supply base while maintaining quality standards, regardless of manufacturing location.

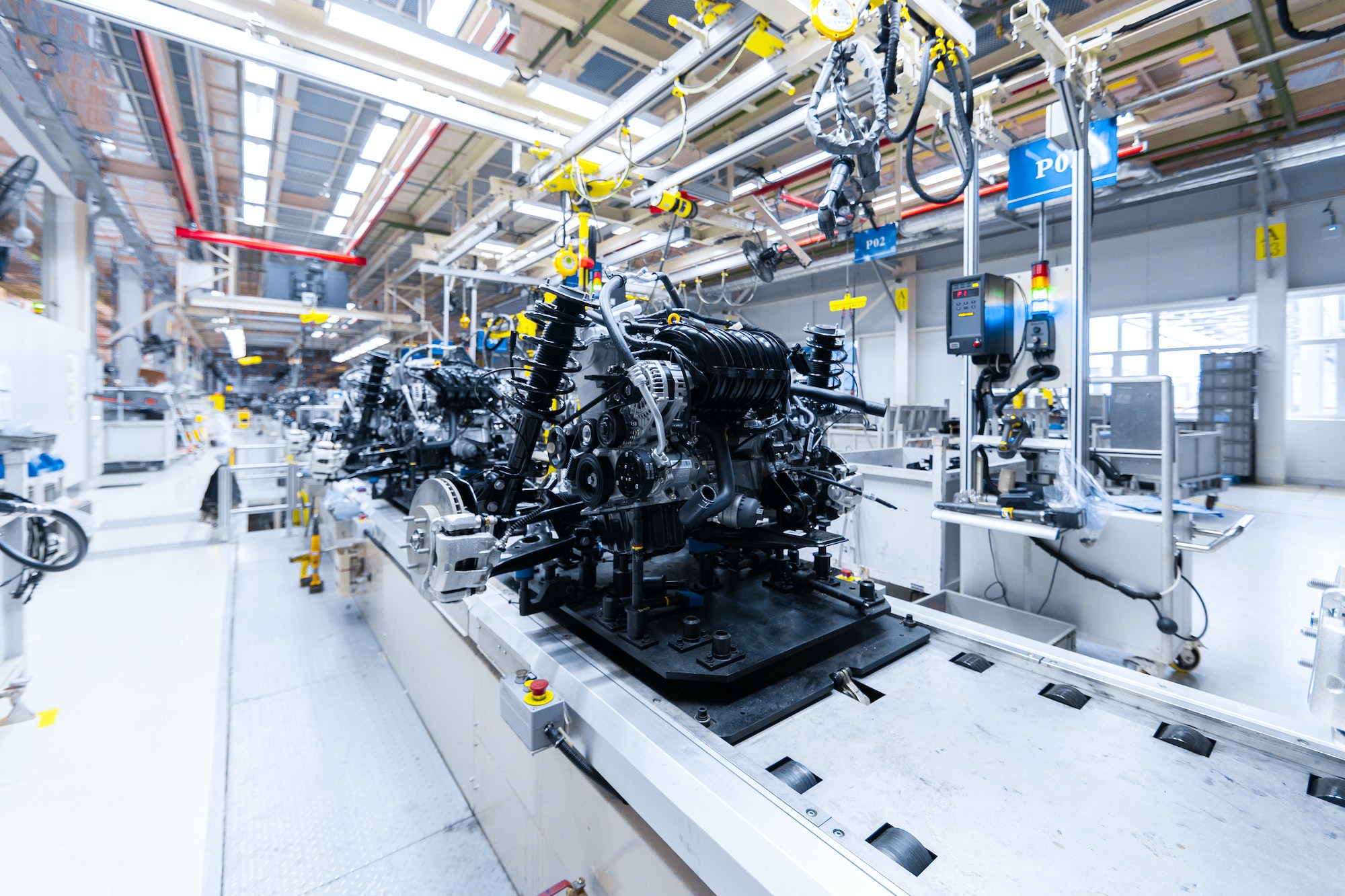

Experienced and innovative contract manufacturing and assembly of precision machined parts for tailored engineering solutions.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur.

Industrial & Power Tools

Automotive

Medical

customers

Our trusted partners